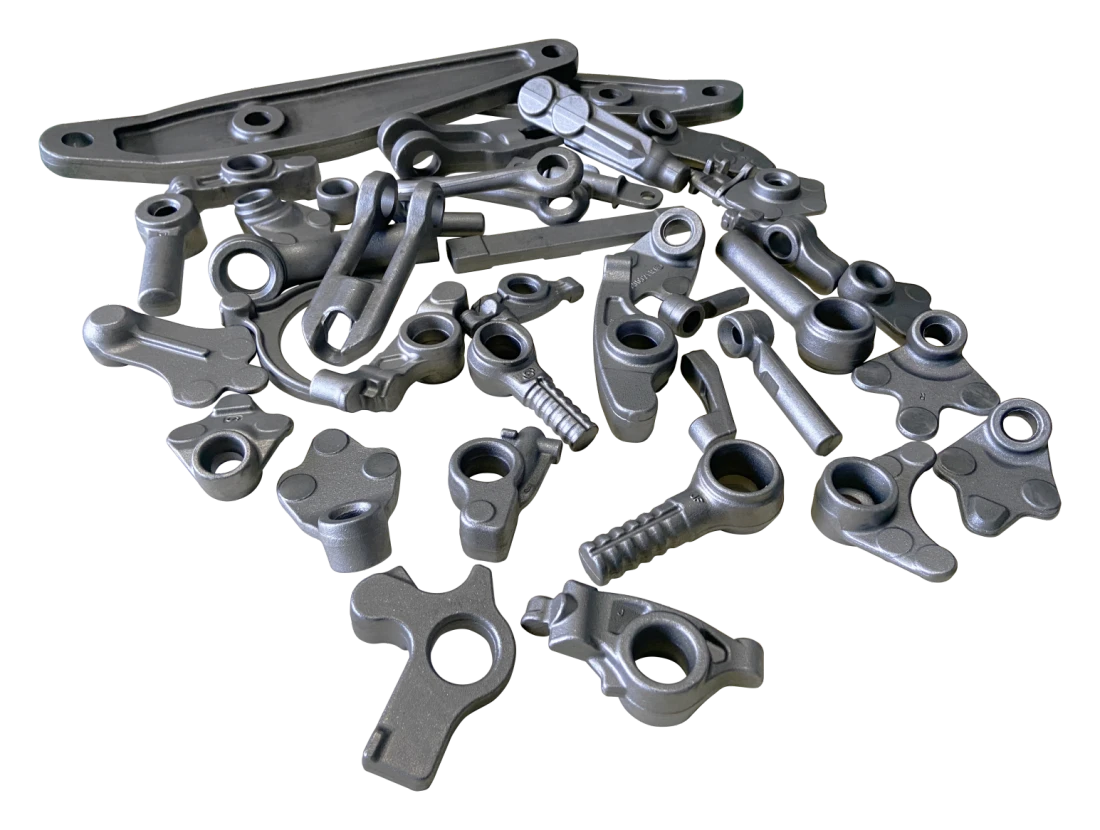

CASTING

Casting is SANJING’S strengths, we have rich experience in design and manufacturing. According to your dimensional accuracy and surface roughness requirements to choose the most appropriate casting method, such as sand casting, shell casting, investment casting, lost foam casting and die casting. Below are the general dimensional accuracy, surface roughness, material and cost comparison tables of various casting methods for your reference

SANJING can provide castings, and also supply a complete part after machining with surface treatment and assembly.

In addition to drawing customization, SANJING can also carry out reverse development. As long as you provide a sample, we can design parts with your brand for you, and we will also make your products more competitive in the market in terms of lightweight ,material and heat treatment design.

Casting Method | Dimensional Accuracy | Surface Roughness | Common Materials |

Sand casting | Low | Ra12.5-Ra25 | Cast steel, Cast Iron |

Investment casting | Middle | Ra6.3-Ra12.5 | Cast steel |

Silica sol casting | High | Ra3.2-Ra6.3 | Cast steel,Stainless Steel, Nickel-based Alloy |

Shell mold casting | Middle | Ra6.3-Ra12.5 | Cast steel,Cast Iron |

Lost foam casting | Middle | Ra6.3-Ra12.5 | Cast steel,Cast Iron |

Die casting | High | Ra1.6-Ra3.2 | Aluminum alloy, Zinc alloy |

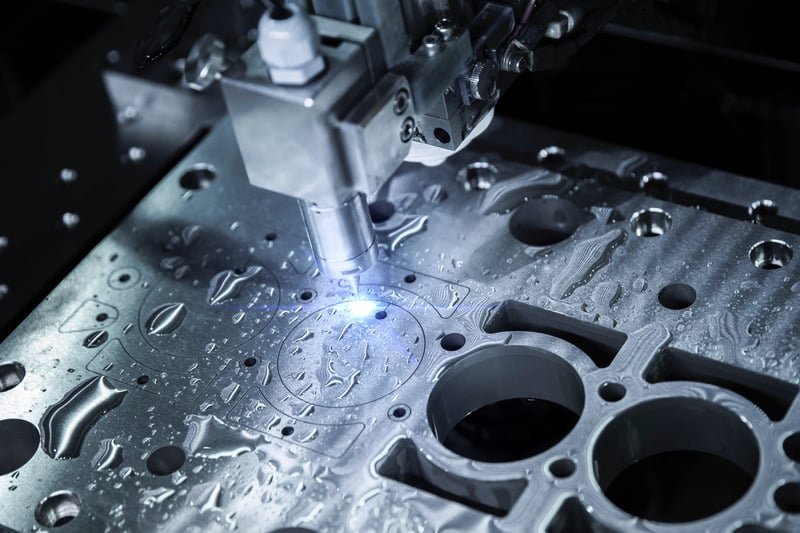

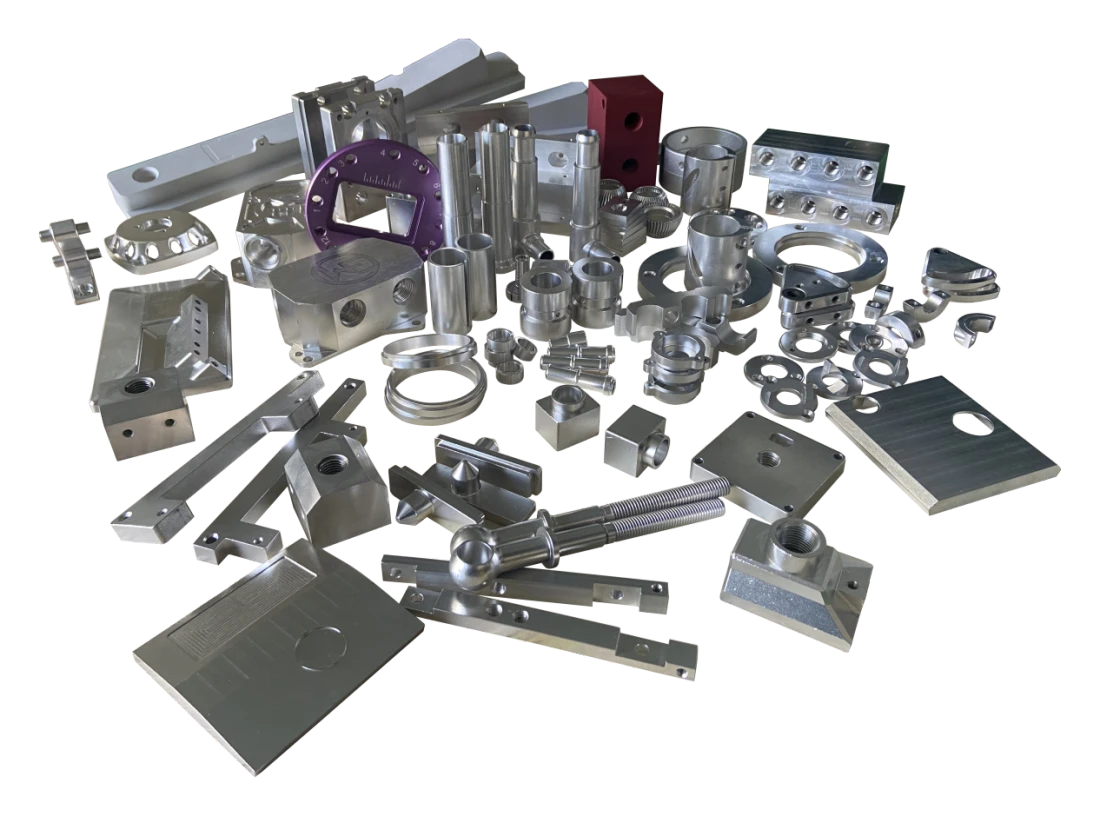

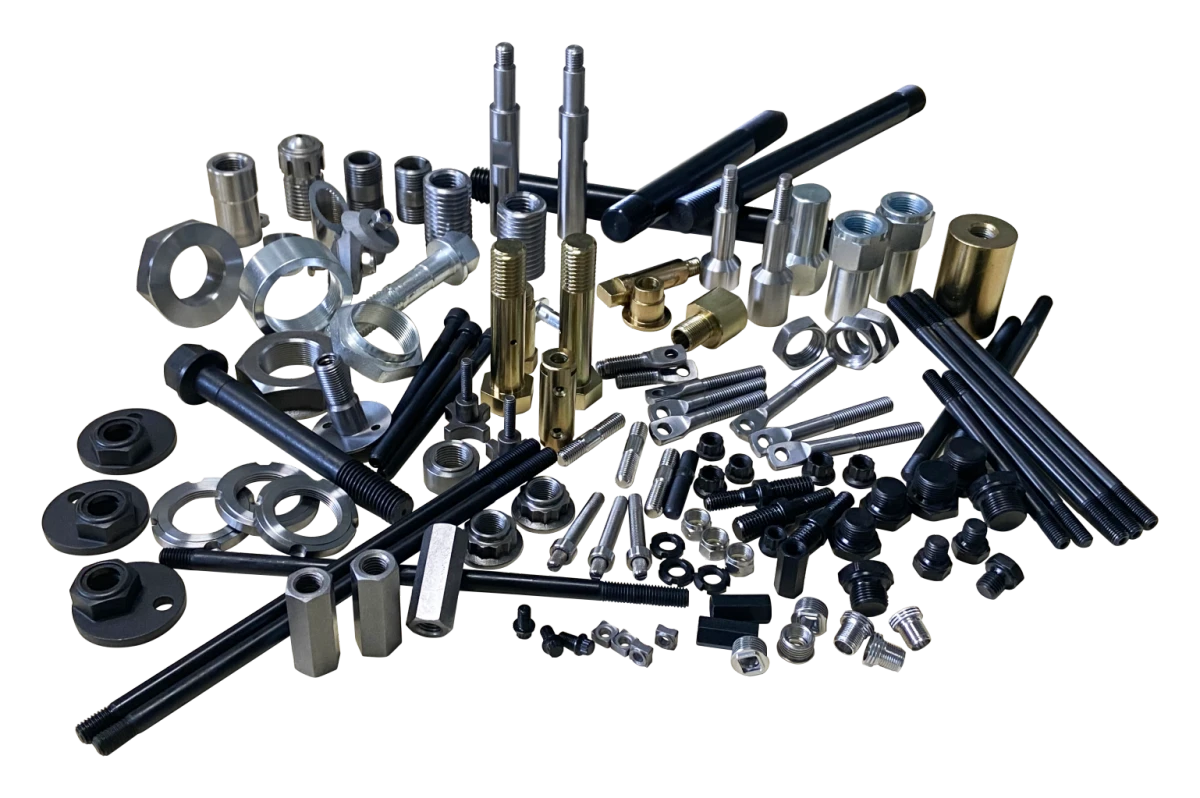

CNC MACHINING

Rich machining experience and complete equipment make SANJING more cost advantage.

We are capable of machining all kinds of materials such as free cutting steel alloy steel, stainless steel, aluminum alloy, copper alloy and so on.

For parts with big volume, we will customize the shape and size of the material to reduce material and machining costs, and we can also arrange a special automated production line for you to improve production efficiency.

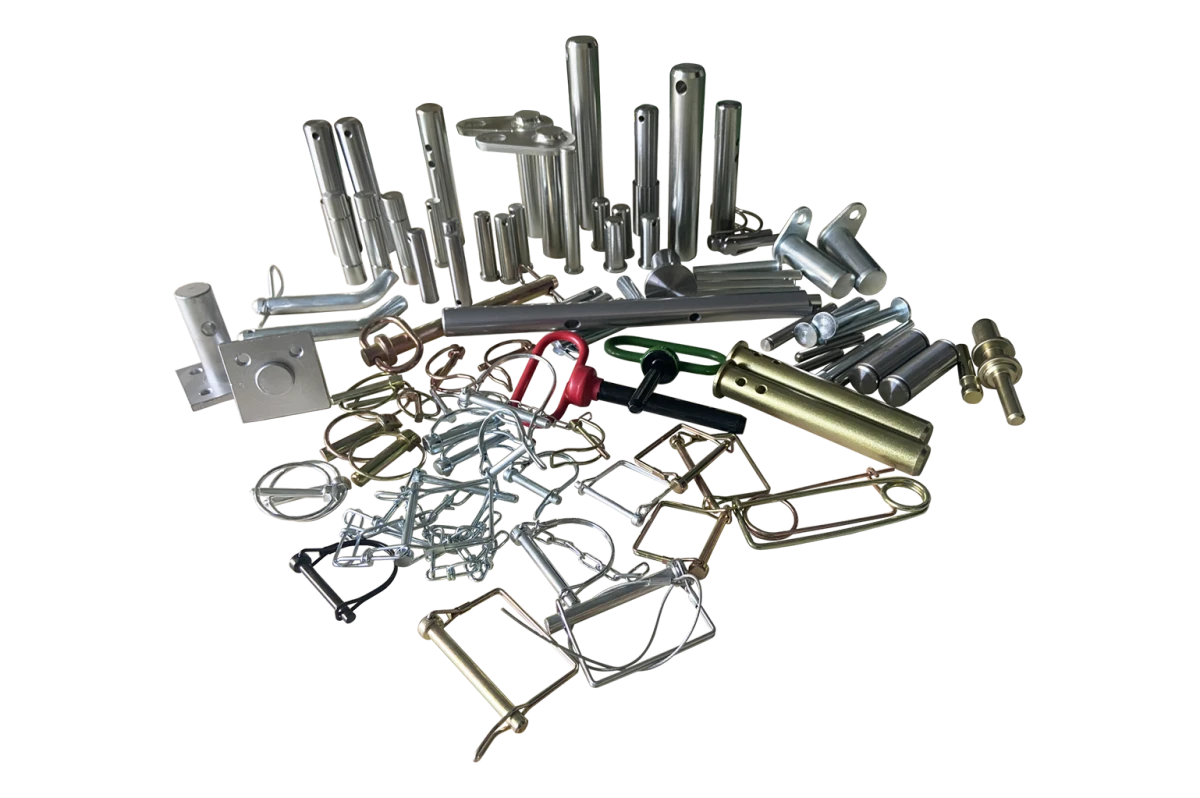

FORGING

Rich experience in forging makes our forging mold design more professional, which brings about the reduction of raw materials and forging process optimization, thereby reducing the cost of material and manufacturing, makes you have more market advantages.

SANJING can supply only forgings or a complete part after machining with surface treatment and assembly.

The factory is well equipped and capable of producing all kinds of large and medium forgings.

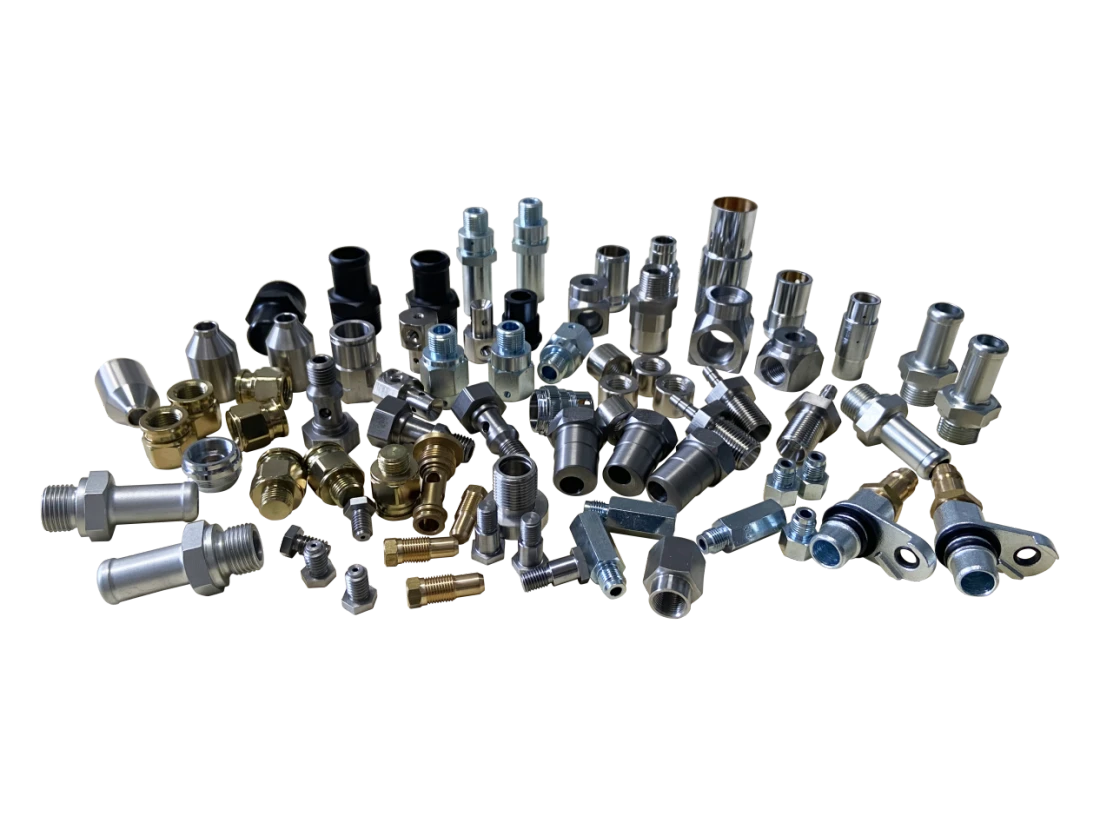

NON-STANDARD FASTENERS

Do not worry about property class and hydrogen embrittlement susceptibility, SANJING is the best choice for your non-standard fasteners.

PLASTIC PARTS

In addition to metal parts, SANJING also provides customers with plastic parts of various materials, such as PE, PP, PVC,PS, ABS, POM, HDPE.

For small batch parts, we will use plastic rods to process the products you need with CNC.

For parts with big quantity, we will make molds first and produce with injection molding machines.

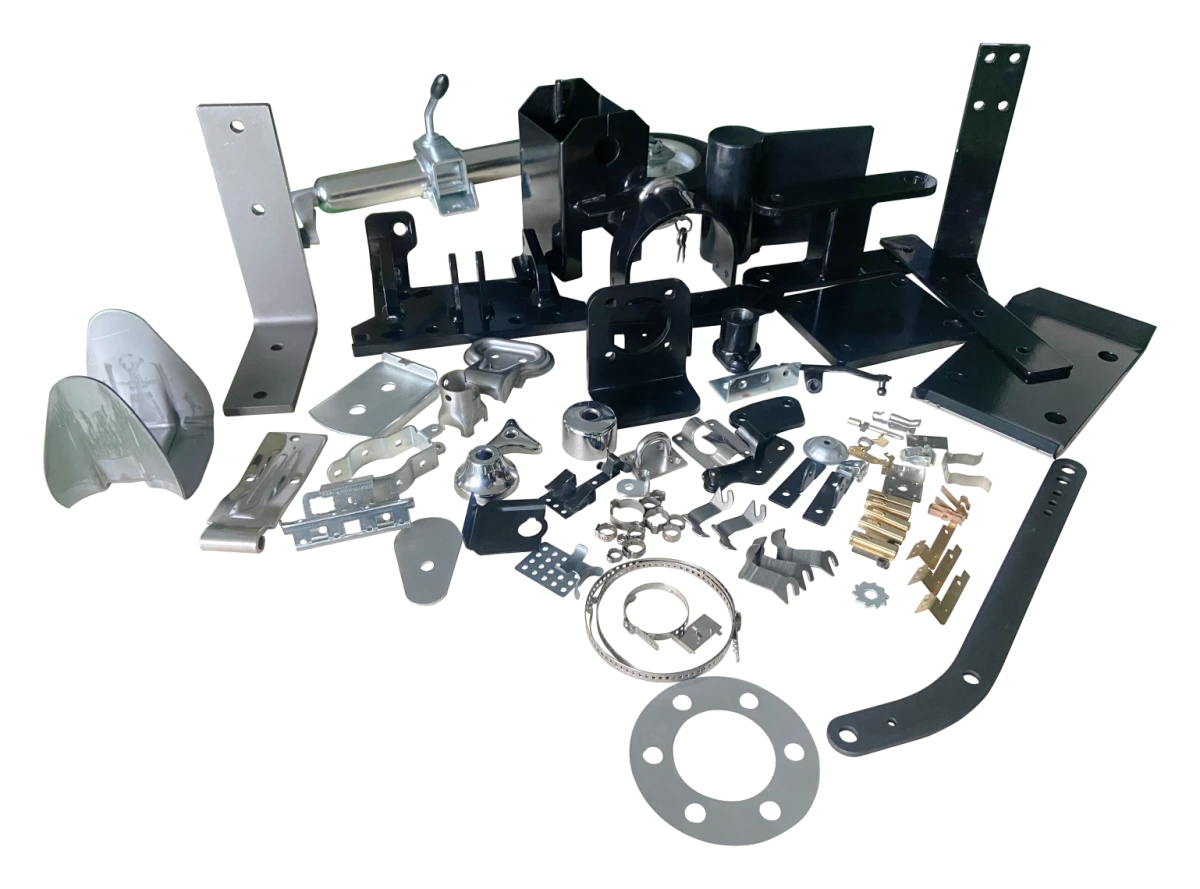

SHEET MetaL PARTS

Stamping, bending laser cutting, flame cutting, welding and CNC machining can be combined to produce the sheet metal parts you need SANJING can also design your sheet metal parts into castings which will be more beautiful and the cost will be reduced too.